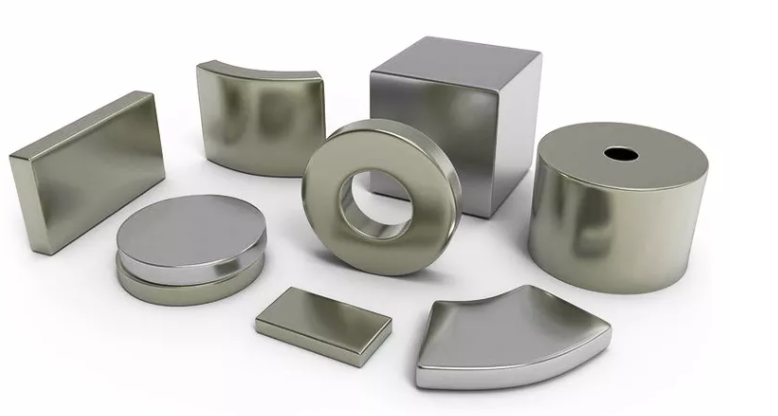

1. Awọn oofa neodymium ni a maa n ṣe lati inu ohun elo ti o ni erupẹ ti neodymium, irin, ati boron ti o wa ni papọ labẹ ooru giga ati titẹ lati dagba ọja ti o pari.

2. A fi adalu lulú sinu apẹrẹ tabi eiyan ati ki o gbona si iwọn otutu ti o ga ki o bẹrẹ lati yo ati fiusi.

3. Ni kete ti ohun elo naa ba de aaye yo, o waye ni iwọn otutu yii fun akoko kan titi ti o fi fi idi mulẹ sinu nkan kan laisi awọn ela tabi awọn dojuijako laarin awọn patikulu.

4. Lẹhin ti imuduro ti o ti waye, oofa naa le ṣe ẹrọ sinu apẹrẹ ti o fẹ ati iwọn lilo awọn irinṣẹ gige oriṣiriṣi gẹgẹbi awọn ẹrọ milling tabi awọn lathes da lori awọn pato ohun elo.

5. Awọn egbegbe ti oofa naa le jẹ didan dan bi o ba fẹ ṣaaju ki o to ni bo pẹlu idabobo aabo gẹgẹbi nickel tabi zinc fun awọn idi idiwọ ipata.

Ṣiṣe awọn alaye diẹ sii, jọwọ wo inu inu atẹwe sisan isalẹ:

| Rara. | Sisan ilana | Igbesẹ iṣelọpọ | Isẹ imọ-ẹrọ |

| 1 | Aise Ohun elo Ayewo | 1.ICP-2.chemical Analysis-3.Analyser(C&S) | Iwari Rohs Idanwo Tiwqn Mimọ Analysis |

| 2 | Aise elo Pre-itọju | 4.Sawing- 5. Gbigbe- 6.Ipact Cleaning | Rin irin Gbona Air Gbigbe Isọdi Ipa |

| 3 | Iṣakoso eroja | 7.Ingredient Iṣakoso | Ṣe iwọn Batching Illa Raw elo |

| 4 | Rinhoho Simẹnti | 8.Vacuumizing-9.Melting-10.Simẹnti | Igbale Yiyọ Din Simẹnti |

| 5 | Idinku Hydrogen | 11.Pre-treating-12.Vacuumizing-13.Fi Hydrogen | Ṣaaju-itọju Igbale Pa nipasẹ Hydrogen |

| 6 | Milling | 14.Shattering-15.Grinding-16.Jet Mill-17.Granularity Iṣakoso | Ti n fọ Lilọ ofurufu Mill Idiwọn Rogular |

| 7 | Titẹ | 18. Powder weighting -19.Pre-titẹ - 20.Titẹ -21. Isotatic titẹ | Powder àdánù Titẹ-tẹlẹ Titẹ Isotatic titẹ |

| 8 | Sintering | 22.Vacuumizing- 23.Sintering -24 Ooru itọju | Igbale Sintering Ooru itọju |

| 9 | Ayewo | 25.BH tẹ-26. PCT-27. Idanwo iwuwo -28.Roughcast Ayẹwo | wiwọn oofa Igbeyewo olùsọdipúpọ iwọn otutu PCT Wiwọn iwuwo Ayewo |

| 10 | Ṣiṣe ẹrọ | 29.Grinding -30.Wire gige-31.Igi abẹfẹlẹ inu | Lilọ Ige okun waya Ige abẹfẹlẹ inu |

| 11 | QC ayẹwo igbeyewo | 32.QC igbeyewo ayẹwo | QC ayẹwo igbeyewo |

| 12 | Chamfering | 33.Chamfering | Chamfering |

| 13 | Electrolating | 34.Electroplating Zn 35. Electroplating NICUNI 36.Phosphating 37. Chemical Ni | Electrolating Zn Electrolating NICUNI Phosphating tabi Kemikali Ni |

| 14 | Awo Ayẹwo | 38.Sisanra-39.Ibajẹ Resistance -40. Adhesiveness-41.-Ayẹwo Ifarada | Sisanra Ipata Resistance Adhesiveness Ayẹwo ifarada |

| 15 | Iṣoofa | 42.Pari Ayewo- 43.Samisi- 44.Arraying/Involution- 45.Magnetizing | Ayẹwo pipe Siṣamisi Arraying / Involution Iṣoofa Idanwo Fiux oofa |

| 16 | Iṣakojọpọ | 46. Oofa Flux- 47.Bagging- 48. Iṣakojọpọ | Apo Iṣakojọpọ |

Akoko ifiweranṣẹ: Oṣu Kẹta-15-2023